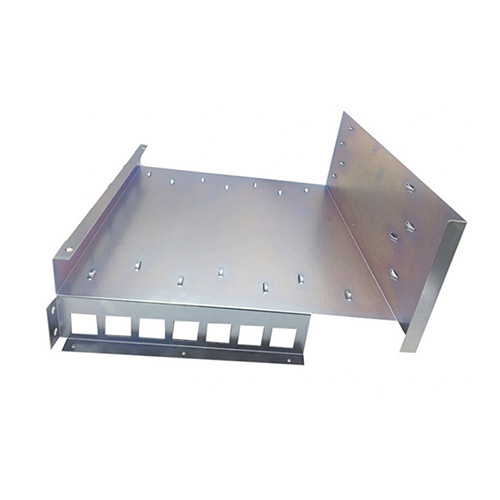

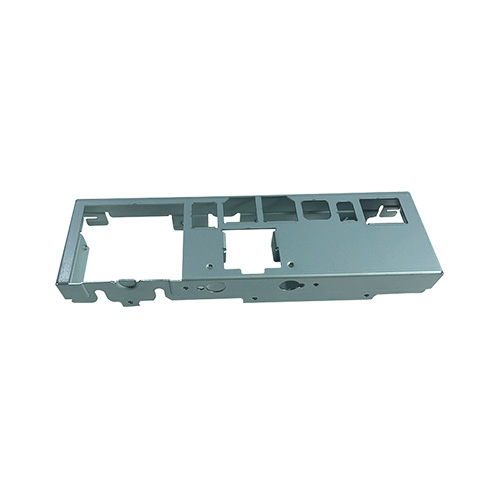

Sheet metal fabrication including:stamping ,cutting,bending,welding

Stamping: Stamping is a process used to shape flat sheet metal by piercing, punching, embossing and performing other operations with a stamping press.

A stamping press is a metalworking machine tool that can precisely shape or cut metal to your specifications. The process involves forming, drawing, trimming, blanking, and/or piercing the metal with a die. Typically, the process can be used for both sheet and coil forms of metal.

Laser cutting: Laser cutting is a technology that uses a laser to vaporize materials, resulting in a cut edge.

Types for laser cutting: There are three main types of lasers used in laser cutting.

CO2, The CO2 laser is suited for cutting, boring, and engraving

Nd (neodymium), Nd is used for boring and where high energy but low repetition are required

Nd:YAG (neodymium yttrium-aluminum-garnet).is used where very high power is needed and for boring and engraving.

All can be used for welding

1. Supports All Materials ,Laser cutting supports nearly all types of materials.From aluminum and copper to stainless steel and even titanium,some material is hard for CNC machining but it is easy for laser cutting .Because of the laser beam’s high temperature, it can cut through nearly all types of materials, regardless of strength or hardness.

2.Flexibility; Laser cutting does not require an exchange of tools for each separate cut. The same setup is suitable for cutting a lot of different shapes within the same material thickness. Also, intricate cuts do not pose any problems.Same time laser cutting creates smooth edges.

3. Extreme Precision :Accuracy is one of the primary advantages of laser cutting when compared to other thermal cutting methods.

4.Automation :Laser cutting can be automated. It supports Computer Numerical Control (CNC) systems. There are CNC laser cutting machines that work in conjunction with a computer program.The job needs little manpower as contemporary laser cutting machinery is highly automated. An experienced machine operator still plays a big role in the final quality but the speed of cutting and little need for manual labour result in lower costs compared to other cutting methods.

5.Energy Efficient and Speed :While it still requires energy, laser cutting is considered more energy efficient than many other cutting methods,Laser cutting is a lot quicker than traditional mechanical cutting methods. Especially in the case of more complex cut.

Bending is a manufacturing process that produces a V-shape, U-shape, or channel shape along a straight axis in ductile materials.

Metal bending advantages :

Aesthetics :The lack of weldments guarantees on nice visual for your project.

Coating:A smooth surface is a great canvas for coating procedures, leaving a better result.

Less mistakes:Compared welding it need less manual labour,the less manual labour means less mistake.Automatic bending systems provide accurate results.

What is welding : is a fabrication process that joins materials, usually metals or thermoplastics, by using high heat to melt the parts together and allowing them to cool, causing fusion.

According to the specific welding process, welding can be subdivided into other special welding such as gas welding, resistance welding, arc welding, induction welding and laser welding. If you need know more please contact zeping precision now .